SIVB 506 formed wall sections at Douglas Aircraft in Santa Monica CA.

|

Using a Version Brake to curve the machined tanksections at Santa Monica

(SIVB 506).

|

Sub-assembly bay at the Douglas Aircraft Co. Space Division, Huntington

Beach CA. Complete SIVB 210 in distance.

|

SIVB 509 in the "Pandjuris" welding rig, Huntington Beach.

|

SIVB 509 in Pandjuris welding rig.

|

SIVB 510 tank segments.

|

SIVB 507 final segment (1967).

|

Automated Pandjuris welding machine. SIVB 507 final weld.

|

Pandjuris welder in action ( SIVB 507).

|

Trimming end of tank 507.

|

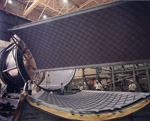

SIVB 506

|

SIVB 507

|

Looking through SIVB 509 as section of 510 is placed into storage rack

(1967).

|

SIVB 501 tank with 511 segments in foreground. |

SIVB 514 being positioned for welding of outer rings.

|

(Images

files are approximately 300K to 500K in size)